- The Supply Chain business: an overview

- What is Business Intelligence in Supply Chain management?

- Value of Business Intelligence for the Supply Chain

- Challenges in Supply Chain management solved by Business Intelligence

- Business Intelligence for the Supply Chain: use cases

- How to implement Business Intelligence for Supply Chain management

- Identifying your main concerns and problems

- Defining your key metrics, KPIs, and data sources

- Defining your IT project scope

- Developing your Business Intelligence solution

- QA and transfer

- Conclusion

Any supply chain is a complex phenomenon. No matter how short it may be, it is inherently difficult to control and manage as it, by definition, involves several interconnected yet independent parties. After all, ‘supply chain’ refers to a network involving entities, employees, operations, data, and resources required to supply a product or service to an end consumer. Dealing with such sophisticated and multidimensional systems without a reliable supply chain management Business Intelligence solution is extremely challenging, especially under the current circumstances associated with lockdowns, political tensions, and trade wars. Hence, Business Intelligence in the supply chain can be viewed as a crucial factor for the survival of any logistics company. In this piece, we will examine the role it plays.

The Supply Chain business: an overview

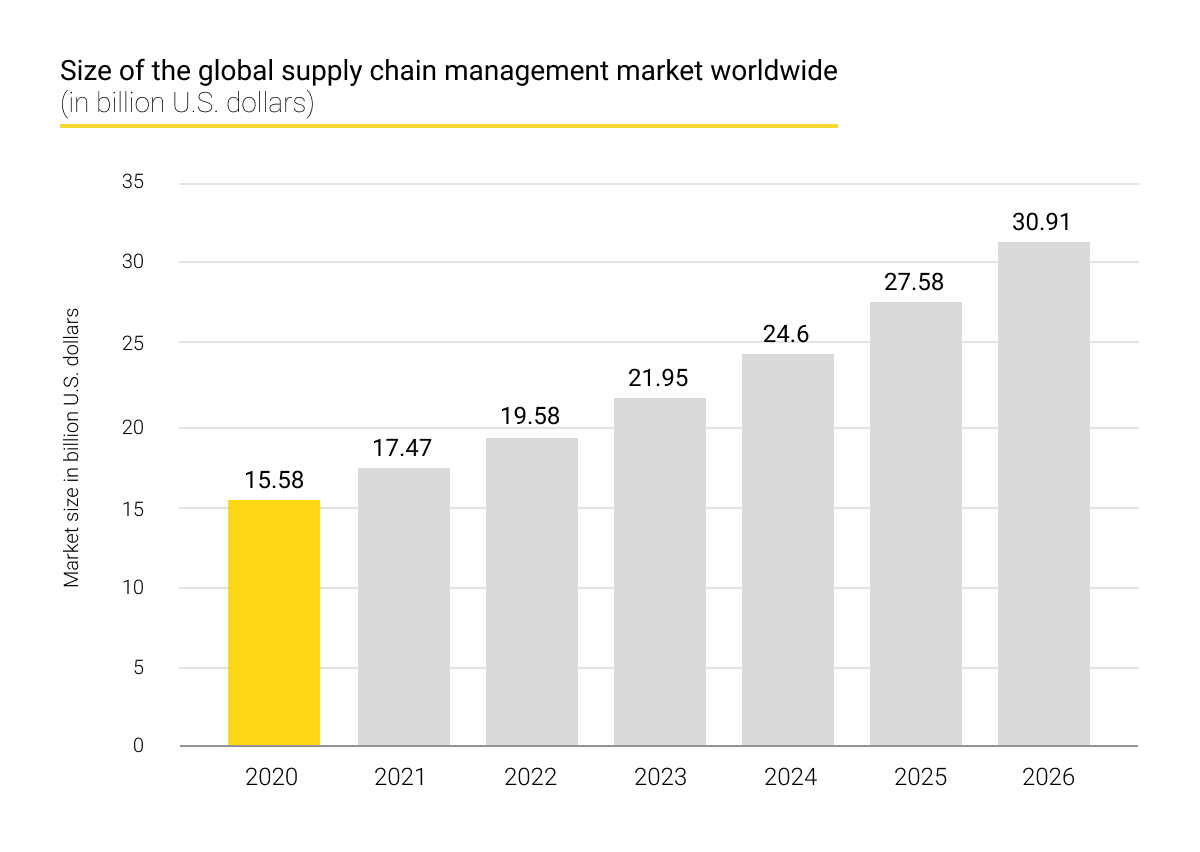

As of now, the supply chain business is experiencing significant growth. Back in 2020, its size was $15.58 billion, while in 2025, it is projected to reach $27.58 billion. This growth could be even more impressive, however, it is hindered by severe disruptions caused by the factors mentioned above. That is to say, lockdowns, political tensions, and border closures are likely to stay with us. These new risk factors make themselves felt against the background created by such ‘classical’ and ‘habitual’ disruptors as mergers and acquisitions, extreme weather conditions, factory fires, business sales, cyberattacks, IT issues, and loss of talent.

Indeed, as Statista reminds us, the number of supply chain disruptions worldwide is growing rapidly: back in 2019, 3,700 supply chain disruptions occurred. In 2020, there were 6,192. As for 2021, the number amounted to a staggering 11,642. All these disruptions inflict heavy losses on the world economy and cost various organizations around the globe “an average of $184 million per year,” as a 2021 survey indicated. What makes matters worse, in some regions the average price to pay for supply chain disruptions is even higher! For instance, in the US, “the estimated average annual cost to respondents' organizations” is as high as $228 million.

Hence, to stay competitive and cost-effective in such a challenging environment, supply chain companies have to apply every possible tech advancement and IT solution to foresee risks, prevent disruptions, and deal with their consequences. Real-time Business Intelligence in supply chain analytics is definitely one of the remedies to try in this respect.

What is Business Intelligence in Supply Chain management?

The key mission of Business Intelligence solutions in any industry is to assist companies with making the right decisions by informing them about their current situation, building projections, and identifying trends based on the data available to them. Namely, this technology is intended to:

- Help management teams track corporate inefficiencies, recognize bottlenecks, and take relevant steps to remove such obstacles;

- Update all involved employees about the state of affairs via informative scorecards and customizable dashboards covering all applicable KPIs, indicators, and available metrics;

- Keep track of progress and recent developments;

- Ensure better collaboration and visibility by aggregating heterogeneous data dispersed among individual departments.

It is possible to attain these ambitious goals if your Business Intelligence solution can handle such tasks as:

- Automatically collecting data in real-time with no manual input;

- Processing and merging it to build reports;

- Storing that information in an easily accessible yet safe fashion;

- Displaying data via scorecards and dashboards;

Performing data analysis and making projections.

Value of Business Intelligence for the Supply Chain

If you obtain a custom-built Business Intelligence solution tailored specifically to your supply chain needs, you will immediately start benefiting from such new opportunities as:

- Fine-tuned demand and inventory management. As a result, your company will be adapted not only to seasonal customer behavior patterns, but also to sudden fluctuations, acts of God, and other unanticipated events.

- Transparent and effective distribution management. Goods will be delivered to your end clients via the most optimal channels.

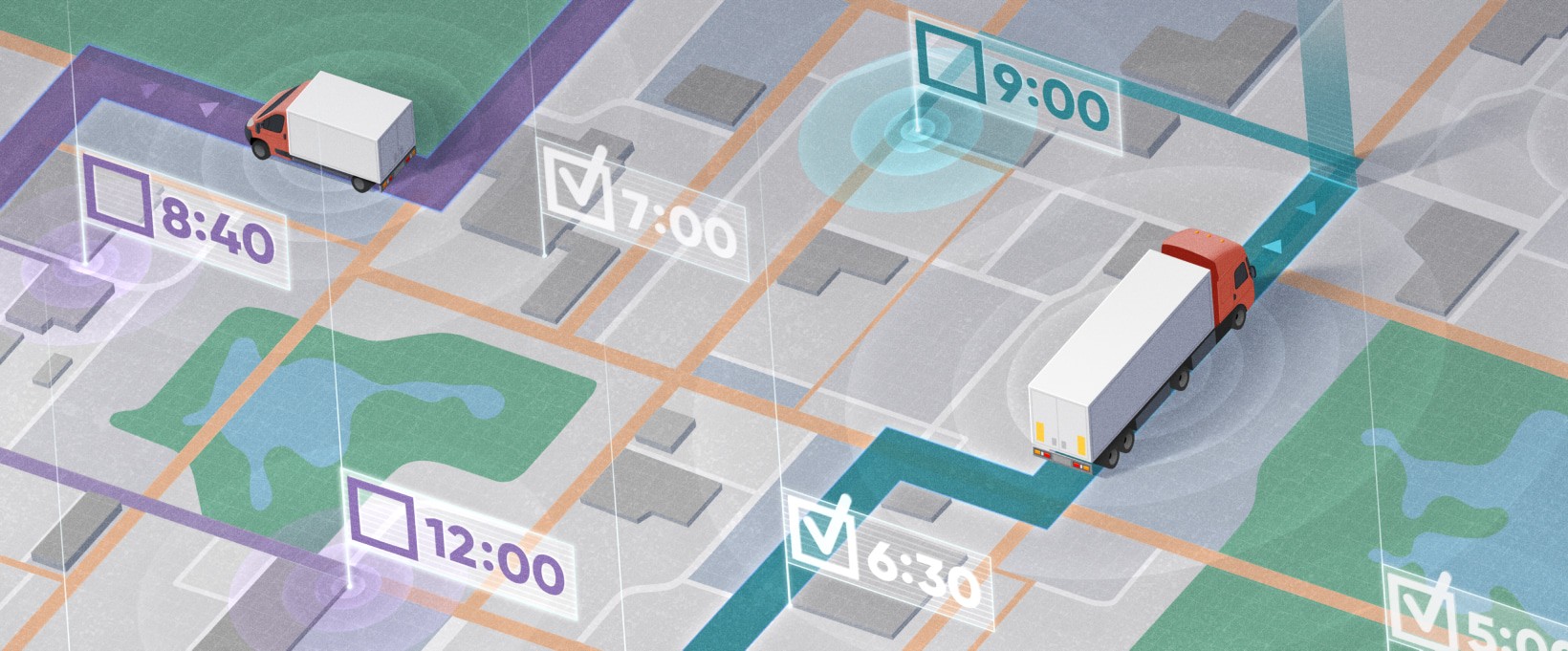

- Transparent transportation management. This capability will enable you to not only track how your products move from one location to another but also to make decisions and introduce changes on the go.

- Various decision-making tools. Data visualisation features and projections allowing you to track KPIs and set new goals.

With all these opportunities at your disposal, your business will capitalize on:

- Increased return on data usage. You will generate more revenue and be able to continue investing in your core business activities.

- Strengthened competitiveness and improved client service. You will win more loyal customers. In such a competitive industry, reputation and trust are invaluable assets.

- Data-driven decisions and all weak spots identified. You will cut costs, save time and resources, and be in the right position to drive more and more value.

- Optimized workflows. You will streamline your operations and boost the efficiency of every employee and business partnership.

Challenges in Supply Chain management solved by Business Intelligence

With all these capabilities in place, you will be in the right position to handle all the typical challenges a supply chain company may face. With a custom-built Business Intelligence solution with sufficient functionalities, the following problems from the list provided by the Institute of Entrepreneurship Development can be totally solved:

- The so-called ‘black swan events,’ including armed conflicts and disease outbreaks with inevitable closures;

- Material scarcity;

- Higher freight prices;

- Port congestion;

- Unpredictable demand.

Business Intelligence for the Supply Chain: use cases

Andersen, as a leading provider of custom Business Intelligence solution development, has built an impressive portfolio of case studies and use cases:

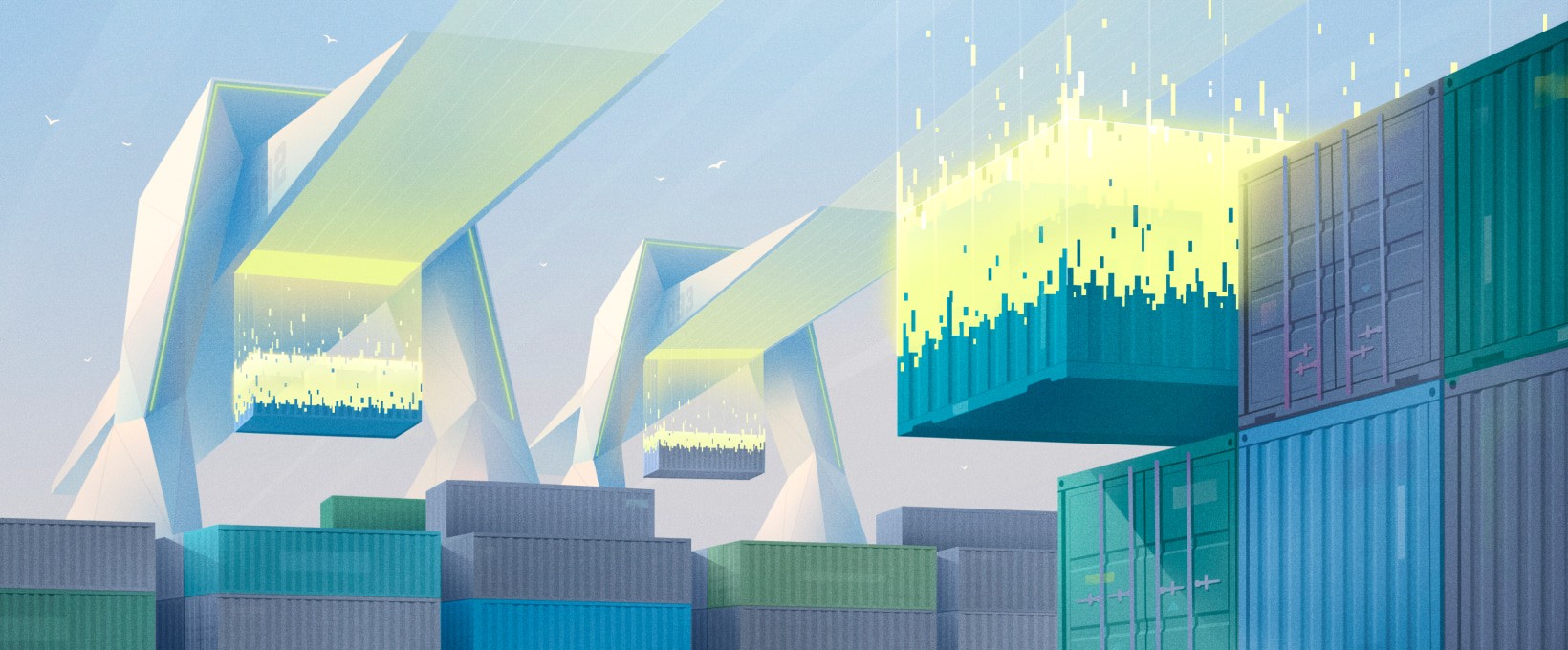

- Andersen’s engineers built an advanced data system to manage complex production and logistics operations. As such, it can “monitor, track, systemize, and assign statuses for each piece of transported cargo.” As a result, the customer managed to reduce the overall transportation costs by 10% and reduce their spending on logistics by 9%;

- We also delivered an IoT and Big Data-based logistics solution for railcars capable of “tracking and monitoring entire fleets, cargos, and any asset in real-time.” The resulting tool tracks 181,000 assets and analyzes 1.6 billion data points monthly. On top of that, the customer has become a more responsible and environmentally friendly market player, with 30,000 tons of CO₂ emissions prevented in 2021.

How to implement Business Intelligence for Supply Chain management

Implementing a high-caliber custom Business Intelligence solution with Andersen is a streamlined and well-structured process consisting of the following steps:

Identifying your main concerns and problems

At this stage, our experts will assess your needs, goals, and problems to envision the best way to address them. Andersen’s team possesses deep expertise and knowledge of industry trends to fully grasp your situation and pain points. This is the key prerequisite for success.

Defining your key metrics, KPIs, and data sources

To make your supply chain Business Intelligence solution as helpful as possible, we will examine every aspect you want to cover in detail. At this level, our main task is to understand what information you need, how you want to collect and process it, and what is your desired way of handling and using it.

Defining your IT project scope

Our experts will describe the scope of your IT project in practical terms, including the team assigned, functionalities to be delivered, costs, and deadlines. Andersen is known for its precise estimates and cost-efficiency, as well as for our consistency in delivering IT projects on time.

Developing your Business Intelligence solution

This stage is all about building the Business Intelligence solution itself, in full accordance with your requirements. We practice a truly Agile approach to our work, so you can be sure that every iteration will be as transparent and interactive as possible.

QA and transfer

Finally, we will thoroughly test your product, following the previously agreed scenarios and use cases. As soon as the resulting solution starts to function flawlessly, we help your employees adopt it via knowledge transfer processes.

Conclusion

Under the current conditions, Business Intelligence is a must for any supply chain company that wants to stay afloat. The environment of uncertainty and new emerging challenges requires companies to be both flexible and resilient, which is impossible without a proper Business Intelligence system in place. At Andersen, we master all the needed technologies and skills to build a modern, feature-rich, secure, and high-performing solution for you. Let’s start the discussion today!